When frying on a commercial scale, foaming oil can be a common problem. That frothy, beer-head type foam that sometimes builds up on the surface of frying oil not only looks unsightly but can be a symptom of poor oil management or even oil contamination.

But what causes oil foaming? And how can it be prevented? In this post, we’ll explain the various reasons why your frying oil may be foaming as well as offer some expert frying tips to ensure your oil is always in tip-top, foam-free condition.

Why does oil foam?

Foaming is caused by oil degradation or contamination, which is often the result of frying with oil on too high a temperature, overusing the oil or frying with poor quality oil that contains impurities. Oil foaming can be caused by any of these factors and is often a combination of more than one issue.

When frying with oil some foaming is likely. The moisture in food is heated when it is placed into frying oil and the resulting steam naturally rises to the surface. It’s this effect that creates the characteristic bubbling of frying food. As oil heats up in the frying vat, it becomes more viscous which traps an increasing amount of moisture and air. After repeated use, the moisture, air, starch and other impurities that come from the food items, or are already present in the oil, build up on the surface and create the infamous foam.

How do you minimise oil from foaming when you’re frying?

We have put together some top foam-busting tips:

- Make sure your vat is thoroughly rinsed and dried before you use it. Water never plays well with oil and any detergent residues will degrade oil and encourage foaming.

- Avoid using any copper or iron vats or utensils. These metals are prone to oxidisation and rust – 50ppb of copper can reduce frying life by as much as 50%!

- Minimise the amount of air in your oil when it’s hot. Aim to filter oil when it is cooler (around 50°C) and remember to cover vats when they are not in use.

- Avoid excessive water on the surface of food. For example, it’s good practice to dry chips before introducing them to the fryer.

- Turn off your frying vats when they are not in use. Hot idle oil generally breaks down faster than when it is not in use.

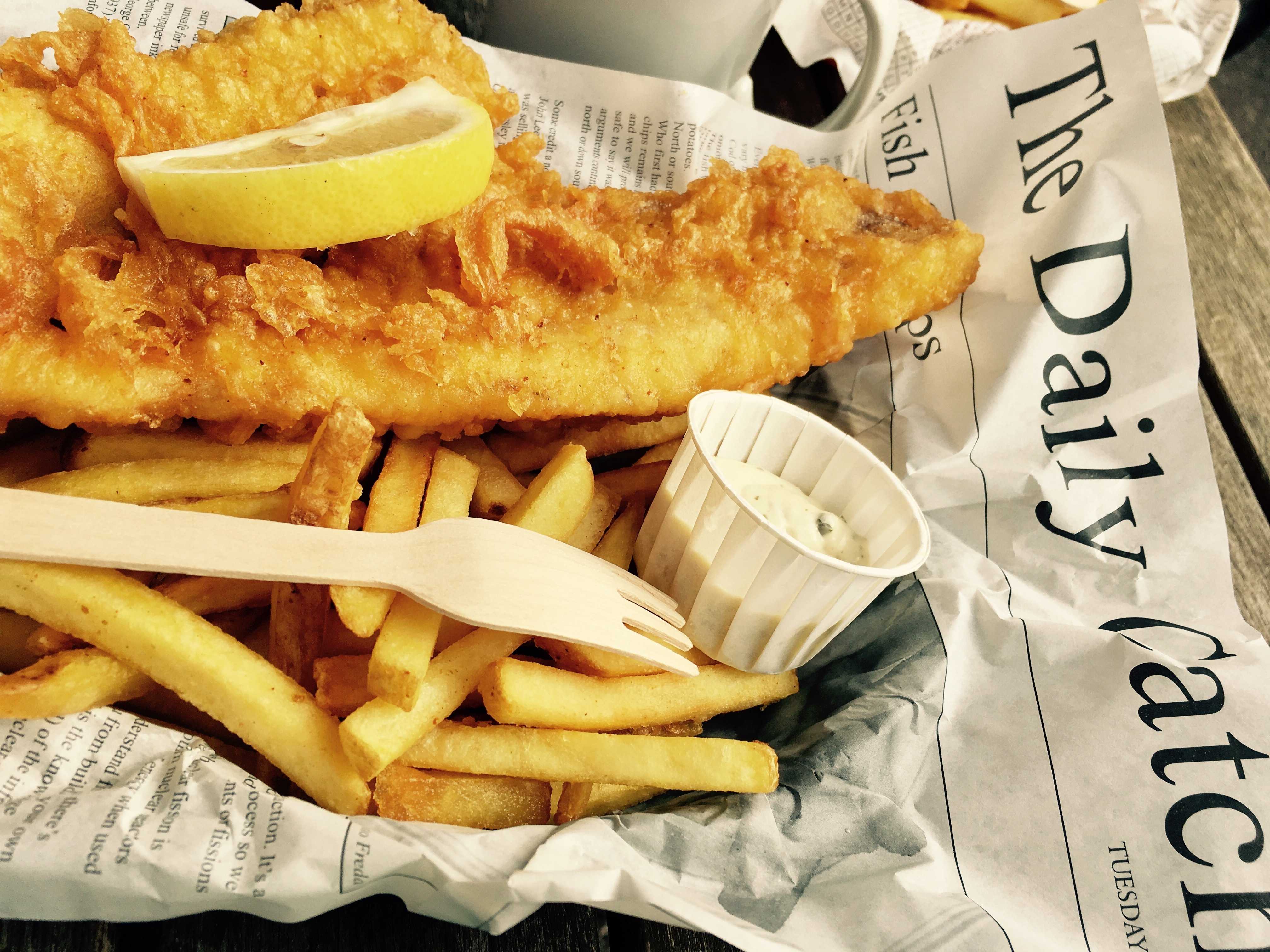

Example of foaming oil:

So, your oil has started foaming. The foam is light in colour with some large bubbles and many smaller bubbles (see above image).

Diagnosing the problem:

- Is oil foaming in one vat or more?

- Does the foaming occur at the beginning or end of frying?

- Has your vat recently been cleaned out?

- Was only one frying vat used for this batch of oil? If no, is the other vat foaming too?

Theoretical cause (assuming fresh oil is being used in a clean vat):

- Contamination – residual detergent or water present in the vat from incomplete or inadequate cleaning.

Test the theory:

- Empty your vat, clean and dry it thoroughly then refill it with a new charge of the same batch of oil. Is the oil still foaming?

- If yes – empty, clean and dry the vat again, but refill with a different date-code oil batch.

The first (and most important) step to preventing your oil from foaming is ensuring you are using the highest quality frying oil. Frymax is naturally a very stable deep-frying vegetable oil, completely free of additives and preservatives, which ensures long and consistent frying life. Get in touch with our team today to learn how Frymax can help you provide superb fried food for longer.

Become a Frymax member today to gain access to exclusive content, expert frying advice and the chance to enter our fantastic competitions.